0.035 Solid Welding Wire: A Comprehensive Guide

When it comes to welding, the choice of welding wire can significantly impact the quality and durability of the joint. One such wire that has gained popularity among professionals is the 0.035 solid welding wire. In this article, we will delve into the details of this wire, exploring its properties, applications, and benefits.

Understanding the 0.035 Solid Welding Wire

The 0.035 solid welding wire is a type of wire used in gas metal arc welding (GMAW), also known as MIG (Metal Inert Gas) welding. It is designed to be used with a shielding gas, typically argon or a mixture of argon and carbon dioxide, to protect the weld from atmospheric contamination.

One of the key features of the 0.035 wire is its diameter, which is 0.035 inches. This size makes it suitable for a variety of applications, including automotive, aerospace, and construction. The wire is solid, meaning it does not have a flux core, which is another type of welding wire commonly used in GMAW.

Properties of 0.035 Solid Welding Wire

Here are some of the key properties of the 0.035 solid welding wire:

| Property | Description |

|---|---|

| Diameter | 0.035 inches |

| Material | Typically made of mild steel, stainless steel, or aluminum |

| Shielding Gas | Argon or a mixture of argon and carbon dioxide |

| Current Range | 30-200 amps |

| Welding Position | Flat, horizontal, vertical, and overhead |

These properties make the 0.035 solid welding wire versatile and suitable for a wide range of applications.

Applications of 0.035 Solid Welding Wire

The 0.035 solid welding wire is used in various industries and applications, including:

-

Automotive: Repairing and manufacturing automotive parts, such as exhaust systems, fuel tanks, and body panels.

-

Aerospace: Joining lightweight materials, such as aluminum and titanium, in aircraft manufacturing.

-

Construction: Welding steel beams, columns, and other structural components.

-

General Fabrication: Welding metal plates, pipes, and other metal components in various industries.

Benefits of Using 0.035 Solid Welding Wire

There are several benefits to using the 0.035 solid welding wire:

-

High Welding Speed: The wire’s small diameter allows for faster welding speeds, which can increase productivity.

-

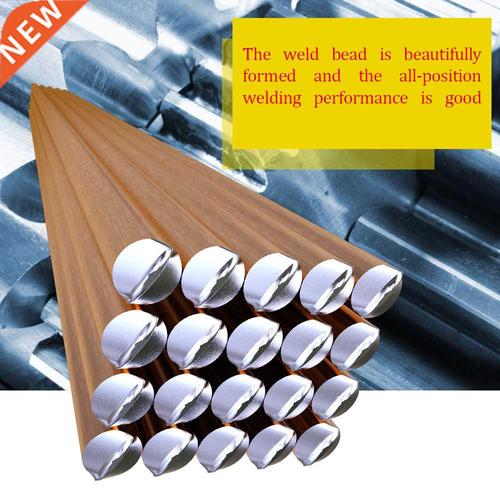

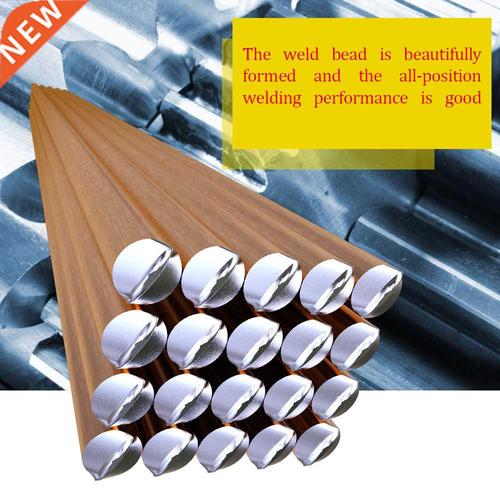

Good Welding Quality: The wire produces high-quality welds with good bead appearance and mechanical properties.

-

Low Spatter: The wire has a low tendency to produce spatter, which can improve the welding process and reduce clean-up time.

-

Easy to Use: The wire is easy to handle and requires minimal setup, making it suitable for both beginners and experienced welders.

Choosing the Right 0.035 Solid Welding Wire

When selecting a 0.035 solid welding wire, it is important to consider the following factors:

-

Base Metal: Choose a wire that is compatible with the base metal you are welding.

-

Welding Position: Select a wire that is suitable for the welding position you will be using.

-

Shielding Gas: Ensure that the wire is compatible with the shielding gas you plan to use.

-

Welding Current: Choose a wire that is compatible with the welding current you will be using.