030 Solid Mig Wire: A Comprehensive Guide

Are you looking to enhance your welding skills or simply curious about the different types of welding wires available? Look no further! In this article, we will delve into the details of the 030 solid mig wire, exploring its characteristics, applications, and benefits. By the end of this read, you’ll have a thorough understanding of what makes this wire a favorite among welders worldwide.

What is 030 Solid Mig Wire?

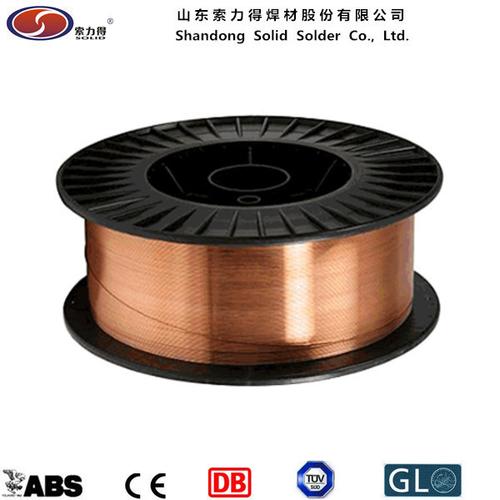

The 030 solid mig wire, also known as ER70S-6, is a type of solid wire used in gas metal arc welding (GMAW) or metal inert gas (MIG) welding. It is designed for use with a shielding gas, typically a mix of argon and carbon dioxide, to protect the weld from atmospheric contamination. This wire is widely used in various industries, including automotive, construction, and metal fabrication.

Composition and Specifications

Let’s take a closer look at the composition and specifications of the 030 solid mig wire. This wire is made of a low-hydrogen, mild steel electrode, which ensures excellent weld quality and reduces the risk of cracking. The chemical composition of this wire includes a minimum of 0.12% manganese, 0.03% phosphorus, and 0.03% sulfur, which contribute to its excellent weldability and mechanical properties.

| Chemical Composition | Minimum Percentage |

|---|---|

| Manganese | 0.12% |

| Phosphorus | 0.03% |

| Sulfur | 0.03% |

The diameter of the 030 solid mig wire ranges from 0.030 to 0.035 inches, making it suitable for a variety of welding applications. This wire is available in different lengths, such as 10 feet, 25 feet, and 100 feet, to accommodate your specific needs.

Applications

The 030 solid mig wire is versatile and can be used for various applications, including:

-

Welding mild steel and low-alloy steel plates, sheets, and bars

-

Repairing and fabricating automotive parts

-

Joining steel structures in construction

-

Welding aluminum and stainless steel with the appropriate flux-cored wire

Benefits of Using 030 Solid Mig Wire

There are several benefits to using the 030 solid mig wire:

-

Excellent weld quality: The low-hydrogen composition of this wire ensures that the welds are free from porosity and cracking, resulting in a high-quality finish.

-

High productivity: The 030 solid mig wire provides a stable arc and excellent wetting action, allowing for faster welding speeds and increased productivity.

-

Easy to use: This wire is user-friendly and requires minimal setup, making it suitable for both beginners and experienced welders.

-

Cost-effective: The 030 solid mig wire is an affordable option that offers great value for money.

Choosing the Right 030 Solid Mig Wire

When selecting the 030 solid mig wire for your welding project, consider the following factors:

-

Material: Ensure that the wire is compatible with the material you are welding.

-

Shielding gas: Choose the appropriate shielding gas, such as a 75% argon-25% carbon dioxide mix, for the best results.

-

Welding current: Adjust the welding current according to the thickness of the material and the desired welding speed.

-

Wire feed speed: Optimize the wire feed speed for the best arc stability and weld quality.