1 4 Fiberglass Solid Plate: A Comprehensive Overview

When it comes to materials that offer a perfect blend of strength, durability, and lightweight properties, the 1 4 fiberglass solid plate stands out as a top choice. This article delves into the various aspects of this remarkable material, providing you with an in-depth understanding of its characteristics, applications, and benefits.

What is a 1 4 Fiberglass Solid Plate?

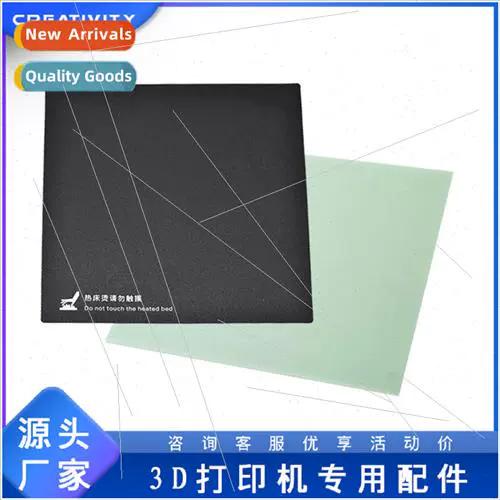

A 1 4 fiberglass solid plate is a type of composite material made from fiberglass reinforced with a solid plastic matrix. The “1 4” refers to the thickness of the plate, which is 1/4 inch or 6.35 millimeters. This material is known for its exceptional strength-to-weight ratio, making it ideal for a wide range of applications.

Composition and Properties

The primary component of a 1 4 fiberglass solid plate is fiberglass, which is a reinforcing material made from fine glass fibers. These fibers are woven together to form a strong, flexible fabric. The plastic matrix, typically made of polyester or epoxy, serves as the base material that holds the fiberglass fibers in place.

Here are some key properties of a 1 4 fiberglass solid plate:

| Property | Description |

|---|---|

| Strength | High tensile strength, making it suitable for structural applications. |

| Durability | Excellent resistance to corrosion, UV radiation, and temperature extremes. |

| Weight | Lightweight, making it easy to handle and transport. |

| Thermal Conductivity | Low thermal conductivity, providing good insulation properties. |

Applications

The versatility of a 1 4 fiberglass solid plate makes it suitable for various applications across different industries. Here are some of the most common uses:

-

Boating and marine: The lightweight and durable nature of this material makes it ideal for boat construction, including hulls, decks, and interior components.

-

Aerospace: The high strength-to-weight ratio of fiberglass solid plates makes them suitable for aerospace applications, such as aircraft components and satellite structures.

-

Automotive: The material is used in the automotive industry for parts like bumpers, fenders, and underbody panels.

-

Construction: Fiberglass solid plates are used in construction for applications such as roofing, cladding, and insulation.

-

Electronics: The material’s excellent electrical insulation properties make it suitable for use in electronic devices and components.

Benefits

Choosing a 1 4 fiberglass solid plate offers several advantages over other materials:

-

Strength: The high tensile strength of the material ensures that it can withstand heavy loads and harsh conditions.

-

Durability: The corrosion-resistant and UV-resistant properties of the material make it suitable for long-lasting applications.

-

Lightweight: The low weight of the material makes it easier to handle and transport, reducing labor and transportation costs.

-

Insulation: The low thermal conductivity of the material provides excellent insulation properties, making it suitable for applications where temperature control is essential.

Conclusion

In conclusion, the 1 4 fiberglass solid plate is a remarkable material that offers a perfect balance of strength, durability, and lightweight properties. Its versatility and numerous benefits make it an ideal choice for a wide range of applications across various industries. Whether you’re in the boating, aerospace, automotive, construction, or electronics industry, the 1 4 fiberglass solid plate is a material worth considering.